Electrically & Thermally Conductive Silver Epoxy Adhesive Cold Solder Replacement Long Pot Life

- Views: 68410

- Product Code: Electro-Bond 02LP

- Availability: In Stock

- $0.00

Available Options

Electro-Bond 02LP is Long Pot Life Curing, electrically conducting silver-filled epoxy compound recommended for electronic bonding and sealing applications that require a combination of good mechanical and electrical properties. Electro-Bond 02 is two-part, smooth paste formulation of refined pure silver and epoxy is free of solvents and copper or carbon additives. It develops strong, durable, electrically and thermally conducting bonds and coatings between many different and dissimlar materials such as metals, ceramics, glass and plastic laminates.Electro-Bond 02 cures at room temperature and can be used as a cold solder for heat-sensitive components where hot-soldering is impractical. It also can be used for the assembly and repair of electrical modules, printed circuits, wave guides, flat cables and high frequency shields. "

Typical Properties |

|

| Components | 2 |

| Mix Ratio | 100/6 |

| Working Life @ 25°C | 180 Minutes |

| Hardness, Shore D | 87 |

| Particle Size | 17 |

| Shelf Life | 1 year |

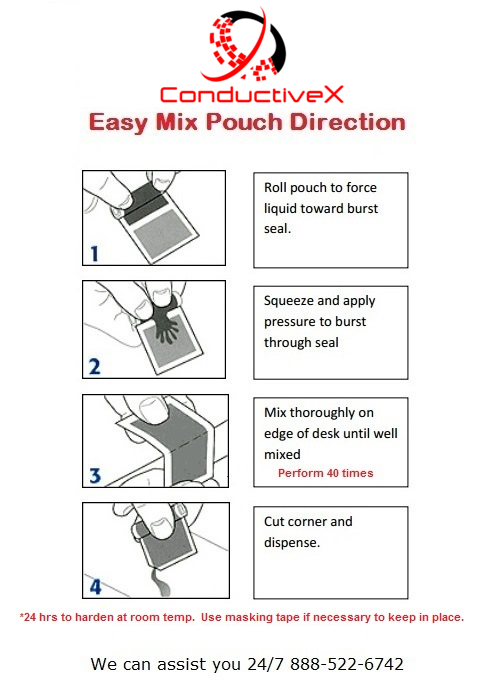

| Cure Type | Room Temp / Heat Cure |

| Cure Schedule | 24 hours @ Room Temp 3 hours @ 65 °C 1 hour @ 120°C |

| Benefits | |

| Designed for high strength application, electrical and thermal properties, perfect bond, cold solder for heat sensitive components. | |

| Typical Applications | |

| EMI & RFI shielding, in the assembly or repair of printed circuit boards, wave guides, electronic modules, flat cable, high frequency shields, connections, circuitry and as a cold solder for high-sensitive components where hot-soldering is impractical | |

Physical Properties |

|

| Appearance | Silver |

| Filler | Silver |

| Viscosity | Paste |

| Substrates | aluminum, copper, magnesium, steel, bronze, nickel, ceramic, glass, circuit board |

| Density @ 25°C | |

| Outgassing, NASA %CVCM | 0 |

| Outgassing, NASA %TML | 0.61 |

| Outgassing, NASA %WVR | 0.13 |

| Compressive Strength, PSI | 13000 |

| Specific Gravity @ 25°C | 2.79 |

| Hardness | 87 |

| Lap Shear Strength | 1000 |

| Reactive Solids Content, % | 100 |

| Shrinkage Linear, IN/IN | 0.003 |

| Tensile Strength, PSI | 9400 |

Electrical Properties |

|

| Volume Resistivity | 6.00 E-04 ohm. cm |

Thermal Properties |

|

| Thermal Conductivity @ 25 °C | |

| Operating Temp | from –50 to +130°C |

| Glass Transition Temp (Tg) | 60°C |

| Thermal Expansion Coefficient, per °C | 0.49 |

| Heat Distortion, °C | 175 |

| Thermal Conductivity W/M-K | 2.99 |

| Thermal Conductivity BTU-IN/HR-FT²-°F | 20.73 |

Tags: conductive epoxy, conductive adhesives, carbon epoxy, carbon epoxies, carbon adhesive, carbon adhesives