Low Cost Silver Epoxy, Electrically Conductive Adhesive, EMI RFI Sheilding System

- Views: 74998

- Brand: ConductiveX

- Product Code: Electro-Bond 06

- Availability: In Stock

- $0.00

Available Options

Electro-Bond 06 represents the newest technology since the introduction of electrically conductive silver compounds. This unique formulation is based on a silver coated ceramic that results in lower material costs without adversely sacrificingthe properties obtained with a pure silver formulation. This concept opens the door to a wide range of applications previously prohibited by the much higher cost of conventional silver conductive. Electro-Bond 06 cures at room tem perature or can be accelerated with mild heat to form a tenacious bond between similar anddissimilar substrates such as aluminum, copper, magnesium, steel, bronze nickel, ceramic, glass, phenolic, and G-10 epoxy glass boards. because of its excellent continuity, has been used extensively in such diversified applications as, microwave EMI and RFI shielding, in the assembly or repair of printed circuit boards, wave guides, electronic modules, flat cable, high frequency shields, connections, and circuitry and as a cold solder. This unique formulation offers ease in handling due to its creamy consistency and versatile application by hand, automatic dispenser, silk-screening, transfer or stamping techniques. "

Typical Properties |

|

| Components | 2 |

| Mix Ratio | 100/5 |

| Working Life @ 25°C | 60 Minutes |

| Hardness, Shore D | 83 |

| Particle Size | 40 |

| Shelf Life | 1 year |

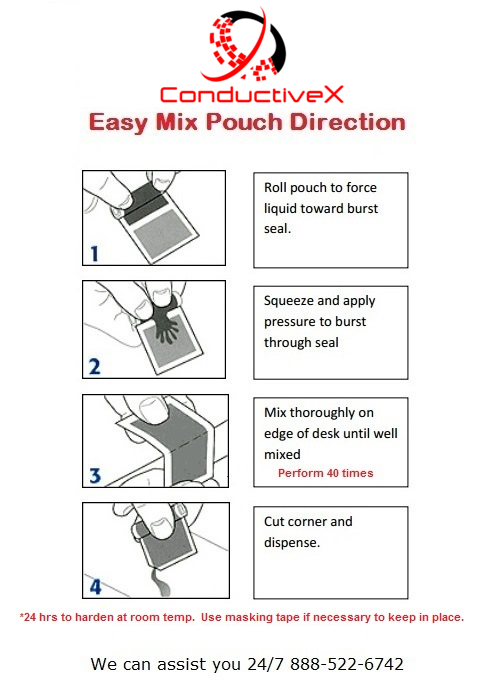

| Cure Type | Room Temp / Heat Cure |

| Cure Schedule | 24 hours @ Room Temp 3 hours @ 65 °C 1 hour @ 120°C |

| Benefits | |

| For high strength application, electrical properties, perfect bond, cold solder for heat sensitive components. | |

| Typical Applications | |

| EMI & RFI shielding, in the assembly or repair of printed circuit boards, wave guides, electronic modules, flat cable, high frequency shields, connections, circuitry and as a cold solder for high-sensitive components where hot-soldering is impractical | |

Physical Properties |

|

| Appearance | Silver |

| Filler | Silver |

| Viscosity | Paste |

| Substrates | aluminum, copper, magnesium, steel, bronze, nickel, ceramic, glass, circuit board |

| Density @ 25°C | |

| Compressive Strength, PSI | 13700 |

| Specific Gravity @ 25°C | 2.59 |

| Hardness | 83 |

| Lap Shear Strength | 8500 |

| Reactive Solids Content, % | 100 |

| Shrinkage Linear, IN/IN | 0.004 |

| Tensile Strength, PSI | 8900 |

Electrical Properties |

|

| Volume Resistivity | 1.70 E-03 ohm. cm |

Thermal Properties |

|

| Thermal Conductivity @ 25 °C | |

| Operating Temp | from –50 to +130°C |

| Glass Transition Temp (Tg) | 60 |

| Thermal Expansion Coefficient, per °C | 0.49 |

| Heat Distortion, °C | 90 |

| Thermal Conductivity W/M-K | 18.37 |

| Thermal Conductivity BTU-IN/HR-FT²-°F | 18.37 |

Tags: conductive epoxy, conductive adhesives, Silver epoxy, silver epoxies, silver adhesive, silver adhesives, flexible conductive silver, flexible conductive adhesive